We have bolstered our marketing team with the appointment of Jacqueline Barker as marketing assistant, to shore up company communications and develop positive customer relations.

Barker, who has been with us for 4.5 years, moves into the team from the customer care department, where she focused on developing and maintaining relationships with our customers, and is therefore well placed in understanding ongoing demand and key customer requirements.

In her new role, she will support the marketing department by assisting on creative campaign delivery and maximising engaging customer contact.

Barker said: “I’m really pleased to have been appointed to the marketing team and support efforts to fulfil our role as our customers’ trusted advisor, and I look forward to engaging with them in creative, dynamic, and informative ways.

“I’m excited to have the chance to work on digital design projects, as it allows me to combine my creativity and passion for design. I love the welcoming, supportive, and collaborative working environment of the office at Melett – the company is consistent in its approach of adding value and maintaining positive client relationships.”

Some of Barker’s key roles will be to assist with new product bulletins, social media content, internal communications, reporting on key business metrics and website administration.

Gareth Flower, Marketing Manager, said: “Jacqueline is a valued member of the team and has found great success working closely with customers to build strong relationships in her previous role. This, combined with her creative skill set, will enable us to improve our communication with customers even further. Her meticulous planning skills, as demonstrated in her assistance and delivery of recent internal events, will be a real asset to the team.”

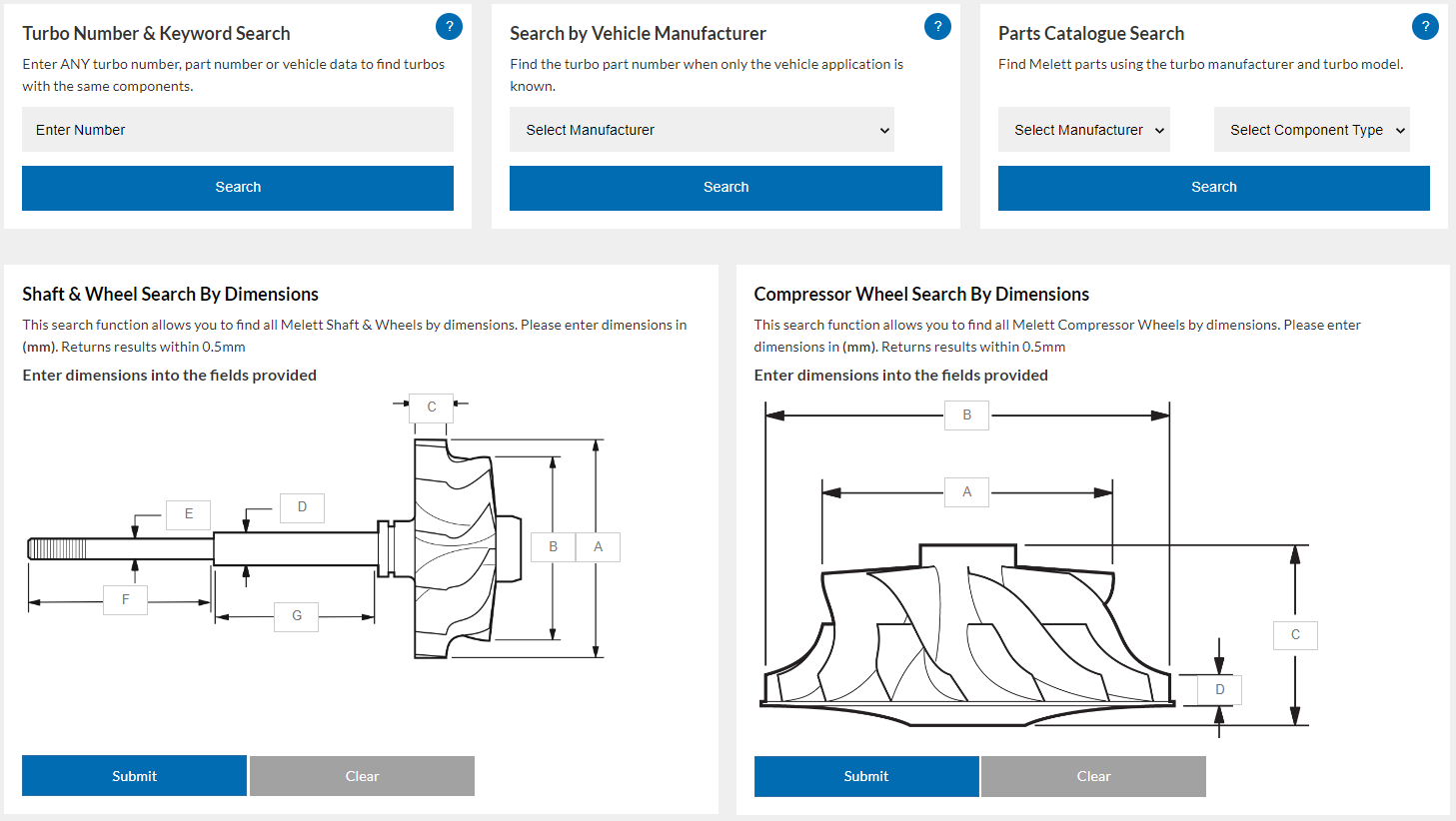

For more information on us, including technical turbocharger resources and locations of our network of turbo specialists, please explore our website: www.melett.com