Melett Parts Production

As the trusted aftermarket brand for precision engineered turbochargers and components Melett’s manufacturing capabilities are unparalleled. Our global production facilities leverage the latest technologies and processes to ensure the highest standards of quality and reliability.

Our core assembly and turbocharger manufacturing operations in Barnsley, UK, employ advanced machining and assembly techniques to produce a wide range of core components to exacting specifications.

To support our European presence, we also have a production hub at our distribution centre in Bydgoszcz, Poland. This facility manufactures a range of our popular core assemblies (CHRAs), working in close coordination with the site’s logistics operations to deliver enhanced responsiveness and efficiency to European customers.

Complementing these facilities, our component plant in Changzhou, China, manufactures precision parts and accessories to support the global supply chain.

Across all of our manufacturing locations, Melett maintains a relentless focus on quality, leveraging stringent quality control measures and continuous improvement initiatives to exceed customer expectations. By optimising our global production and distribution network, we can reliably supply our diverse client base with the high-performance turbocharger repair solutions they require.

Melett Parts Manufacturing Video

With quality at the heart of everything we do, the video takes you on a journey through the manufacturing processes involved in producing Melett precision engineered turbocharger parts. The video shows the Melett Manufacturing Facility, highlighting the latest machinery and technology used to produce the highest quality repair parts.

Melett Turbo Production

Our Turbo Production video is designed to guide you through the extensive research and development, detailed design analysis, in-house and on-vehicle testing involved in producing Melett precision engineered turbochargers. The video concludes with a look at the detailed development process of our new electronic actuators.

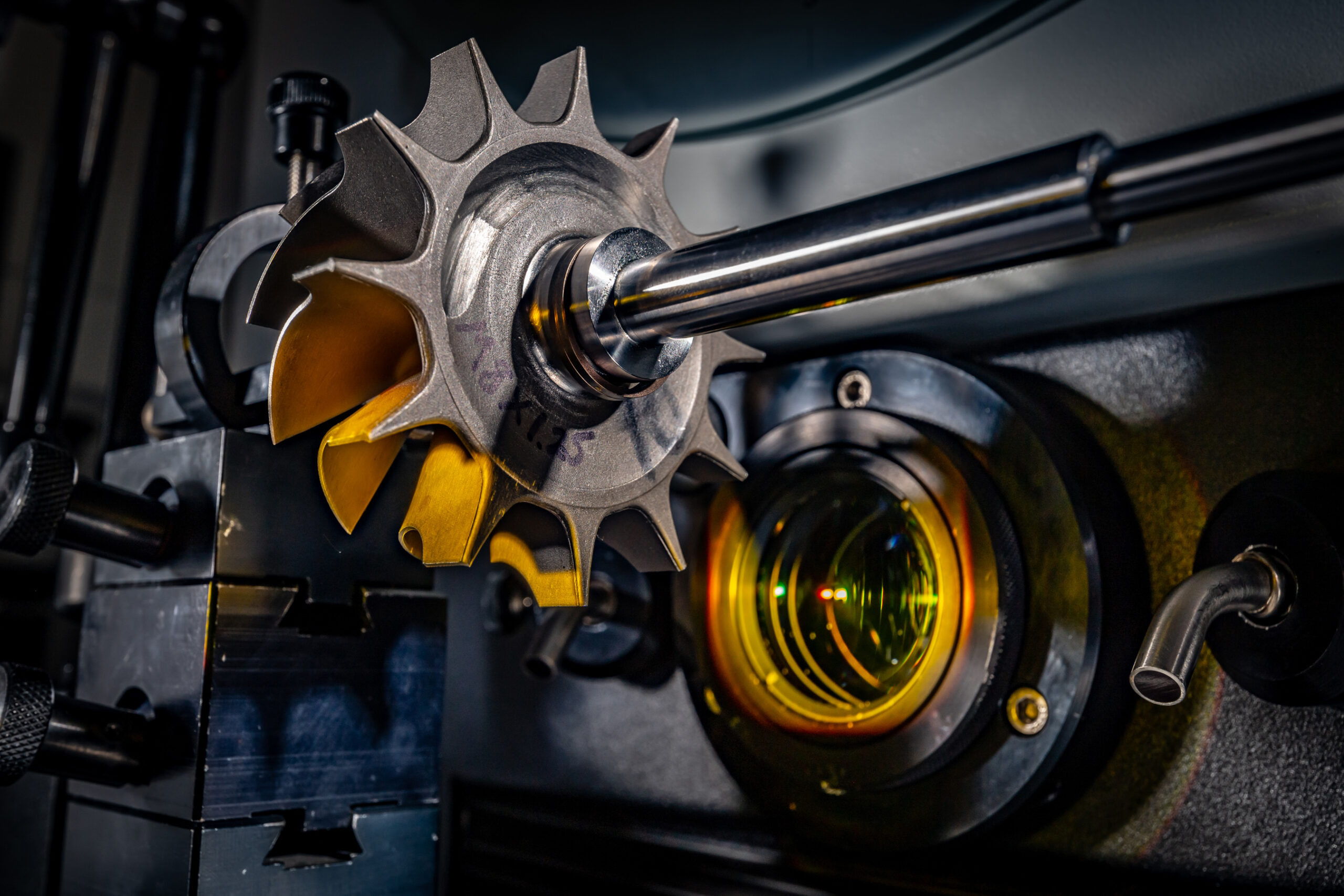

Technical analysis of turbos in development

As part of our rigorous development process, Melett’s in-house engineering team conducts thorough technical analysis of turbos from existing OEM ranges. This includes an in-depth design review and detailed failure diagnosis, allowing our new Melett parts to incorporate improvements to the original component design where possible.

Whenever a new turbo is identified for development, the Engineering team undertakes a full technical analysis of multiple original samples. They meticulously examine dimensions, surface finishes, tolerances, and materials to gain a comprehensive understanding of the entire assembly.

Leveraging vast experience in turbocharger parts and repair, the Melett Technical team speaks the language of turbos fluently. They are able to provide expert advice and support to customers across a wide range of technical repair challenges.

Strong engineering principles

Melett’s in-house engineering team designs all Melett parts. Our engineers possess extensive technical knowledge and expertise, as well as a deep understanding of turbo components and their applications.

Melett engineers utilise 3D measurement capabilities with 2-micron repeatability, along with advanced 3D modelling software, to create precise engineering drawings for manufacturing. The team follows rigorous internal processes to thoroughly evaluate part performance and failure modes, solidifying Melett’s status as the industry expert in quality replacement turbocharger parts.

Strict quality control processes

At Melett, we operate a Quality Management System that complies with the requirements of ISO 9001:2015. This system covers the design, manufacture, and supply of replacement turbocharger parts for the independent aftermarket. From initial analysis to the finished product, we incorporate the highest level of inspection at every stage of production. We also carry out a final quality inspection of every component to ensure the material, dimensions, and surface finishes meet the specified requirements before they are packaged in a genuine Melett box.

Highest quality manufacturing standards

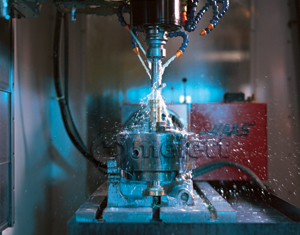

Our significant investment in our own manufacturing facilities gives us complete control over the entire production process, while maintaining the highest quality standards.

The Melett Manufacturing Facility is equipped with the latest machinery and technology, including casting tooling, welding machines, and advanced Japanese CNC equipment with onboard CMM. Our experienced production team has deep expertise in component manufacturing and quality control, ensuring a thorough understanding of the full production process.

In addition to our in-house capabilities, Melett also partners with fully certified ISO/TS16949 quality manufacturers. These external suppliers adhere to the same rigorous quality control principles and have extensive experience producing high-precision parts for OEM turbocharger companies.